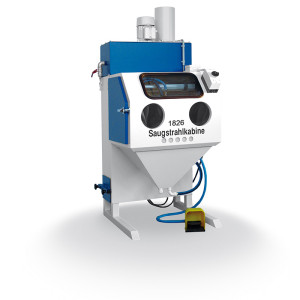

Suction and Pressure Blasting cabinets for professional requirements

Our elaborate and efficient blasting cabinets of the professional class have been attuned to the requirements of our clients in a long lasting development work. Our suction and pressure blasting cabinets are designed for commercial and industrial tasks and are used in all places where surfaces need treatment, for example cleaning, descaling, deburring, roughening, compressing, matting or removing rust.

All cabinets offer:

- powerful technique for professional requirements

- applicability of all commercially available non-disposable abrasives

- easy handling and easy equipping

- universal application when applying manual operation

- clear worktop within the blasting cabinet

- powerful suction

- good illumination of the blasting cabinet

Suction blasting principle or injector principle means that the blasting head is fed with compressed air and abrasive material by two separate hoses synchronously. Within the blasting head the abrasive material is sucked in by the stream of air and mixed with it. Thus, the mixture of air and abrasive material impacts on the work piece with high speed. The pressure blasting method is especially used when there is a demand for powerful output. When using this method, an individually dosed portion of abrasive material coming out of a tank that is under pressure is mixed with streaming air, highly accelerated and fed to the blasting cabinet by the hose of the blasting nozzle.

Both methods do have their advantages. To find out which technique will suit your requirements best, we are proposing a councelling interview.

We are offering cleaning of the abrasive material (cyclone) for all models. The cleaning unit can be applied to the backs of the suction blasting cabinets no. 2642/6, 2642/7, 2642/8 and 4050 or may be used as stand-alone device. Model no. 4055 only allows a stand-alone device for cleaning of the abrasive material. The cyclone consists of a ventilator, precleaner, filter and collection hopper for abrasive material and is equipped with a filling and a cleaning flap. Connections with the blasting cabinet and the filter box are made by flexible hoses. Within the cyclone the blasting dust is already separated from the abrasive material and transported to the filter box. The air is cleaned inside the filter box and released to the work space whereas the cleaned abrasive material are led back to the working circuit.

The offer of various types of dust extractions is an additional advantage of Radler & Ruf blasting systems. You can choose between dust extraction systems for general use or powerful dust extractions for extremely high strains. A subsequent modification of the sand blasting devices is always possible. We are offering different sizes and engine-power classes, so that you can choose a sand blasting cabinet that fits your demands idealy.